Steel hollow sections are types of sectional structural steel. The construction consists of a central core or core, which is surrounded by several layers of steel strips to form a tube. Steel hollow sections are a versatile material that can be used for a variety of applications. They’re commonly used in the construction industry, but an SHS steel tube has many other uses as well. Steel hollow sections are used in a wide range of applications and industries, from playground equipment to recreational boats.

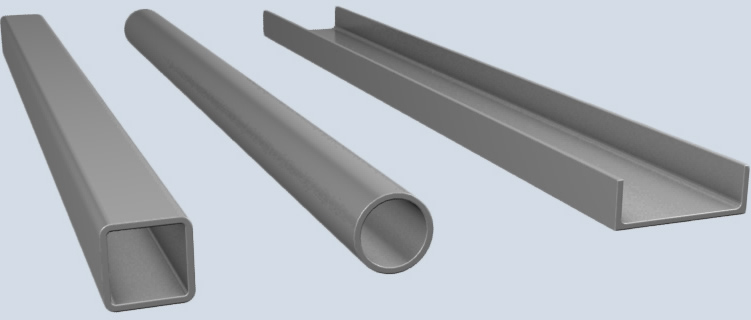

A variety of uses are there for SHSs in the field of construction and engineering due to their lightweight despite a lot of strength. There are three types of steel hollow sections: square hollow sections (SHS), circular hollow sections (CHS) and rectangular hollow sections (RHS).

Square Hollow Sections

The SHSs are one of the most widely used steel sections and have been in use for over 100 years. SHSs are manufactured in sizes ranging from 50mm x 50mm to 500mm x 500mm, with a wall thickness of 3mm to 30mm. The particular grade of steel depends on load-bearing requirements, but typically SHSs are made from mild steel or high yield strength steels such as Grade 32 or Grade 36.

SHSs are used in various construction applications such as buildings, bridges and other types of infrastructure where they provide support during construction stages as well as providing support during operational phases once the project has been completed. Swimming pools. Swimming pools can be made out of steel or concrete; however, they’re more likely than not made with concrete because it’s cheaper than using steel or other materials like fiberglass or aluminium. However, for the best possible quality go with a pool made completely out of SHS steel tube.

Circular Hollow Sections

CHS is a type of steel hollow section, which is also called a rectangular hollow section. It’s a steel profile and must be manufactured with different materials depending on the type of application. CHS are available in different diameters, wall thicknesses and shapes. Each shape has its own characteristics that make it suitable for different applications.

For example:

- Round CHS profiles have circular cross-sections that are used to create round tubes or pipes. Their sizes usually range from 6 mm up to 100 mm in diameter and 40 mm up to 200 mm thick walls.

- Rectangular CHS type of profile has flat parallel sides with rounded corners at both ends that is perfect if you want to create an assembly with very little material waste.

- Square CHS profiles have square cross-sections that can be used as flanges on pipes or tanks where there needs to be some form of pressure resistance because these parts need to withstand high pressures without deforming too much before cracking or breaking apart.

Rectangular Hollow Sections

RHS is a type of steel hollow section that is used in a wide range of industries, including construction, bridges and buildings; transportation (railway and automotive); oil and gas; offshore structures; water treatment plants and chemical plants.

RHS has been often used as a structural element where large amounts of material must be transported quickly without any modification to its design or shape. In fact it can be welded easily by automated equipment which means there is no need for skilled labour on site when building projects are completed.

It’s important to know the different types of steel sections and how they can be used. You need to be sure which one is right for your application before making the purchase. We hope that the above description helped you in pointing out the preliminary differences.

Also Read About: Boost up trading experience with Tesler app